Abstract Large Scale Optimization has many applications in supply chain and smart manufacturing. This chapter discusses the role of Large Scale Optimization in Industry 4.0 and Society 5.0 which deals with digitalization and networking of manufacturing and social sectors.

The current book looks into “Large Scale Optimizations in Supply Chains and Smart Manufacturing” which corresponds to what is called Industry 4.0 in Germany and respectively Society 5.0 in Japan. This article wants to introduce these two concepts which are based on digitalisation. This results in an increasing amount of data which is generated, collected and processed – the so called “Big Data” – and this again needs the methods described in this book to make a better use of them.

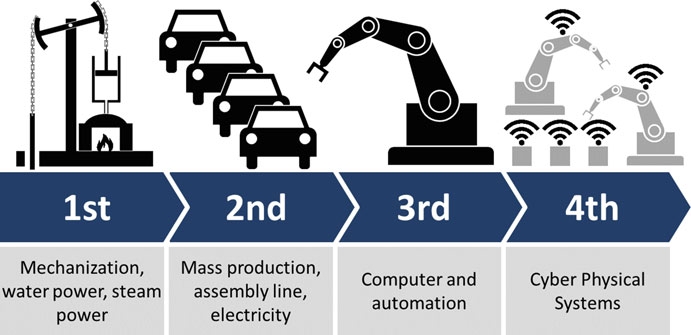

The term Industry 4.0 was first introduced in Germany around 2011 and means the fourth Industrial Revolution. The first Industrial Revolution was a Mechanisation made possible through the use of steam and water power which lead to an increased efficiency. The second Industrial Revolution is characterised through Mass Production of goods, like the conveyor belts for cars by Henry Ford. The third Industrial Revolution was driven by Computerisation and Automation of the production process.

The fourth Industrial Revolution now is the next phase in Digitalization and Networking applied to the manufacturing sector. A so-called digital twin of all assets in a company – machines, materials, people – allows a simulation of all processes from the design to the production to the end of life of products. Suppliers and customers are also digitally linked in Smart Processes as well as Smart Products collect data about their usage. All this may enable a Smart Service (Fig. 1).

Whereas Industry 4.0 implies the digitalization of manufacturing, we have to see that all other aspects of business up to our private life will be digitalized too. In Germany this is reflected in the High-Tech Strategy 2020 of the German Government [2] with six fields of priority:

- The digital economy and society

- The sustainable economy and energy

- The innovative workplace

- Healthy living

- Intelligent mobility

- Civil security

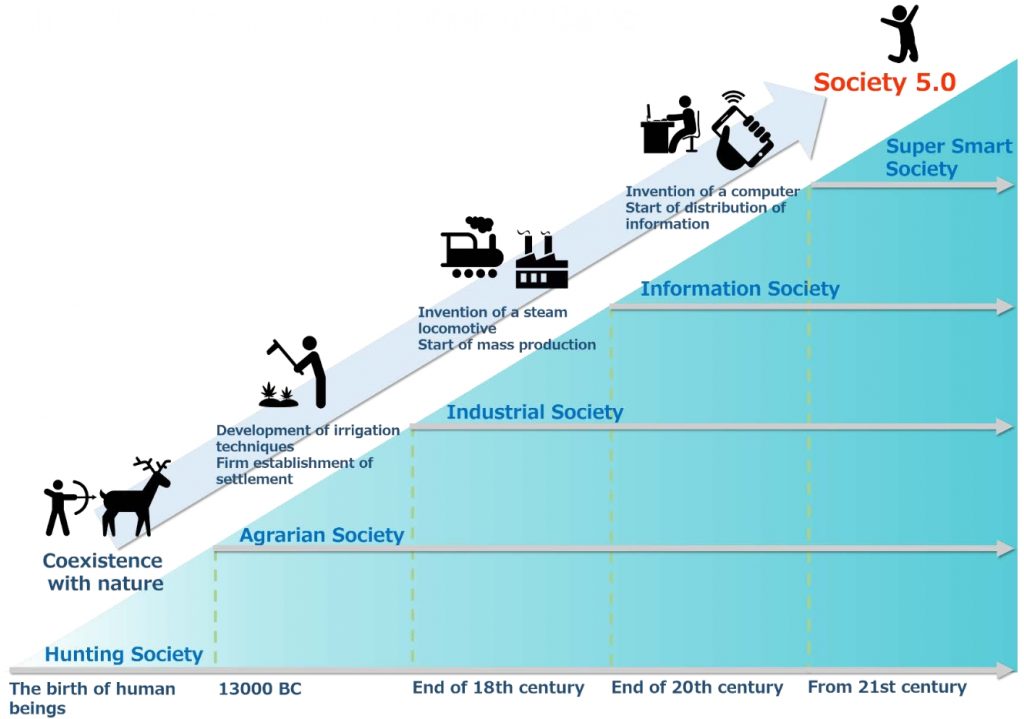

A very similar approach is taken in Japan. Here the manufacturing is not in the centre, but the whole society. The Society 5.0 or the Super Smart Society, introduced in the fifth Basic Plan for Science and Technology, is characterised through Information Technology (IT), especially Artificial Intelligence, that will change many things in business and everyday life (Fig. 2).

Society 5.0 is a more comprehensive expression as it implies that the changes will affect many aspects of the whole society. However, coming back to the focus of this book – value chain and smart factory – we have to look at this part of Society 5.0 and here there are many analogies to Industry 4.0. At the Cebit 2017 fair at Hannover in Germany, the Japanese Ministry for Economy, Trade and Industry (METI) introduced the concept of “Connected Industries” to realise its vision of the Society 5.0 [4].

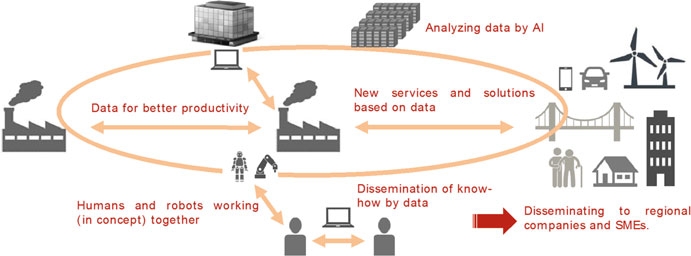

In the centre of the concept “Connected Industries” is the industrial production, which is still the backbone of the Japanese Economy. The following picture gives a good impression of the company in the centre and its connections with external entities.

On the left side are the partners along the values chain. These can be suppliers or other industrial customers, with which business is done. Currently the exchange of information with external partners is not optimal developed in Japan, so “Connected Industries” strives to improve that (Fig. 3).

On the right side of the central company we see the other end of the value chain: potential customers. The deficit here is mainly new services through the usage of data. Compared to many American Companies, that are built on a new data-driven business model – only think of the taxi-app “Uber”, of “Facebook” or the online trader “Amazon” – Japanese as well as German Companies too, are not strong in this discipline. Both rather produce and sell goods. Their strength is high quality goods, but the future will change away from goods going to services. Young people do not want to own a car, they only want to use it. Today aircraft makers do not have to buy a jet engine any more, instead of a big investment they now can just pay per minute of usage which is only possible by having more sensors producing data which enables a predictive maintenance of the engine and thus a cost reduction.

Such new business models built on Digitalisation can also be a smart product, which is enhanced with sensors and enabled by IT to give better usage support. A machine tool can have a display for example with more information about the manufacturing of the products, thus supporting the workers. A refrigerator can order food by itself or a washing machine can wash, when electricity is very cheap. There are many new opportunities, we have to find them.

On the upper side of the picture the support of these activities by data centres and Artificial Intelligence (AI) is shown. AI will be fundamental to handle the vast amounts of data and create new value for new business models.

Finally, more effort has to be put on the human-machine collaboration. Also here AI can help as it also enables to understand and disseminate expert know-how, so the “Meister” of old times can be a machine in the future.

For all these described activities we need an exchange of data. Inside a company it is no problem to set up a secure standard. However, exchanging data with outside entities needs a reliable framework [5].

Connecting data and using data efficiently will encourage innovation, better productivity and dissemination of technology. For this purpose, the current book delivers many methods to analyse Big Data.

References

- Hill, R., Devitt, J., Anjum, A., Ali, M.: Towards in-Transit Analytics for Industry 4.0. In 2017

IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and

Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and

IEEE Smart Data (SmartData), pp. 810–817. IEEE, (2017) - The new High-Tech Strategy Innovations for Germany: Federal Ministry of Education and

Research BMBF, (8/2014). https://www.bmbf.de/en/the-new-high-tech-strategy-2322.html - Toward realization of the new economy and society.: Keidanren, (April 14, 2019). https://

www.keidanren.or.jp/en/policy/2016/029_outline.pdf - Connected Industries Tokyo Initiative: METI ministry of economy, trade and industry,

(2017/10/02) https://www.meti.go.jp/english/policy/mono_info_service/connected_industries/

index.html#press - Source.: https://www.meti.go.jp/english/press/2017/pdf/1002_004b.pdf

© Springer Nature Switzerland AG 2019

M. Fathi et al. (eds.), Optimization in Large Scale Problems, Springer Optimization

and Its Applications 152, https://doi.org/10.1007/978–3‑030–28565-4_1